Hi! In the mid of year 2016 I’ve made this project: a stereo amplifier to improve my TV audio You know, LCD TV’s speakers are so… @#[]! I’ve choosed to use a classical vacuum tube design: a push pull of EL84 tubes drived by ECC82. Output 12W of power per channel.

12W seems not too much but… hey! I can guarantee that my 60 sqm living room are very well sonorized with half of that power.

EL84 Push pull <– Here you can download the zip file with PCB’s ready to print, schematics…

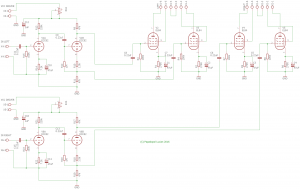

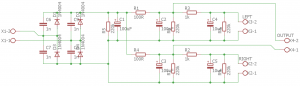

The schematic is very accademic, nothing unusual for this type of amplifier.

As you can see into the next photo, this design is very well know into the literature and online with few little differences like a negative feedback loop (that I have not included) and on driver tube.

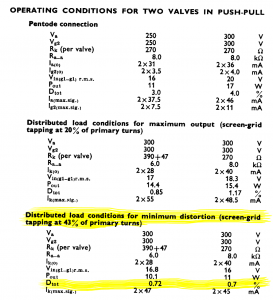

The first section of the ECC82 amplify the incoming signal to drive, the second section. Now it generate an identical but 180° shifted signal on it’s chatode to drive the EL84 tubes in push-pull mode class AB. The tubes are connected in ultralinear mode because avoiding the global negative-feedback loop, I still need some form of feedback in it. Solved using an audio output transformer designed to operate in ultralinear mode. It is a 8k plate-to-plate handmade by me. Take a look at this extract from EL84’s datasheet. The ultralinear mode have such low distortion at full power!!!

I ve choosed the ultralinear tap at 43%. If you know how to made such type of transformer you know what I’m talking about… if not, please buy one ready made from Hammond, they have good value for the price.

http://www.hammondmfg.com/1608.htm this is just a suggestion.

The transformer make 90% of the quality of the amplifier because it characterize heavily the sound.

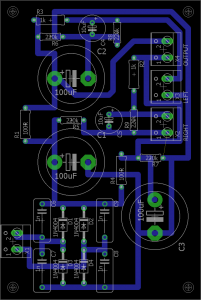

The power supply is straightforward:

It separate the power supply from the left and right preamplifier/driver tubes, into the schematic they are marked X1-X2. The double CLC filtering drop down at the right level the ripple.

X4, the power output is just two positive contacts for the 300V one for the left and one for the right output power transformer. The ground is taken by the X1-X2 ground and then there is no need for another one ground (and the PA-tranny doesn’t need gnd).

Each PA transformer is made by 4000+4000 turns of Ø0.14mm CuEn (copper enameled) wire. The secondary winding is 4+4 ohm so 75+75 windings of Ø0.8mm CuEn. The magnetic core is a EI96/80 column size is 32x32mm weight is 1.7Kg each.

The power supply transformer is a 250V @ 200mA plus 3,15-0-3,15 @ 5A The filament winding (3,15-0-3,15) is a bit unusual because I prefer to balance the filaments current grounding the center-winding-tap to the methal chassis of the amplifier. With this trick I can reduce the 50Hz hum made by filament at infinitesimal level.

This power transformer is made by a primary winding of 826 turns of Ø0.4mm CuEn wire (in Italy mains are 230Vca). The high voltage secondary winding is 987 turns of Ø0.25mm CuEn and the low voltage winding for the filament supply is 25 turns of Ø1.4mm CuEn. The core is a EI96/80 column size still remain 32x32mm same weight of the audio transformers.

In total 5.2Kg of iron and copper 🙂

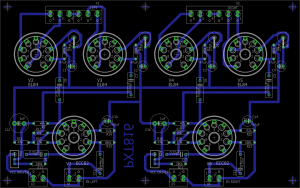

I’ve made some PCB for this project