June 2020. After spending some time searching online for a scintillation material that I could shape at home, I found a Dutch guy named Luuk who had some CsI(Na) crystals available for experiments. After exchanging a couple of emails with him—voilà!—I soon received a nice piece of raw CsI(Na) crystal, possibly originally from Scionix. Thank you, Luuk!

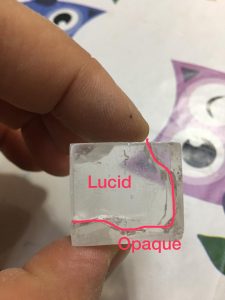

Unfortunately, the crystal cracked shortly after arriving, probably due to thermal shock during transport. Summers can be hot, and postal services aren’t exactly known for gentle handling of sensitive materials like crystals.

After carefully examining the fractures, I realized I could salvage the intact central part of the crystal. I decided to wrap this section with white PTFE tape, serving as a reflective layer, and then couple it on one face with a PMT (photomultiplier tube) for spectroscopy tests.

I cut out the undamaged part of the crystal using a small hobbyist arc saw with very fine teeth. It’s always a good practice to handle scintillation crystals with gloves to avoid contamination.

The initial rough shaping of the crystal surfaces was done with 400-grit sandpaper, giving me an almost rectangular shape.

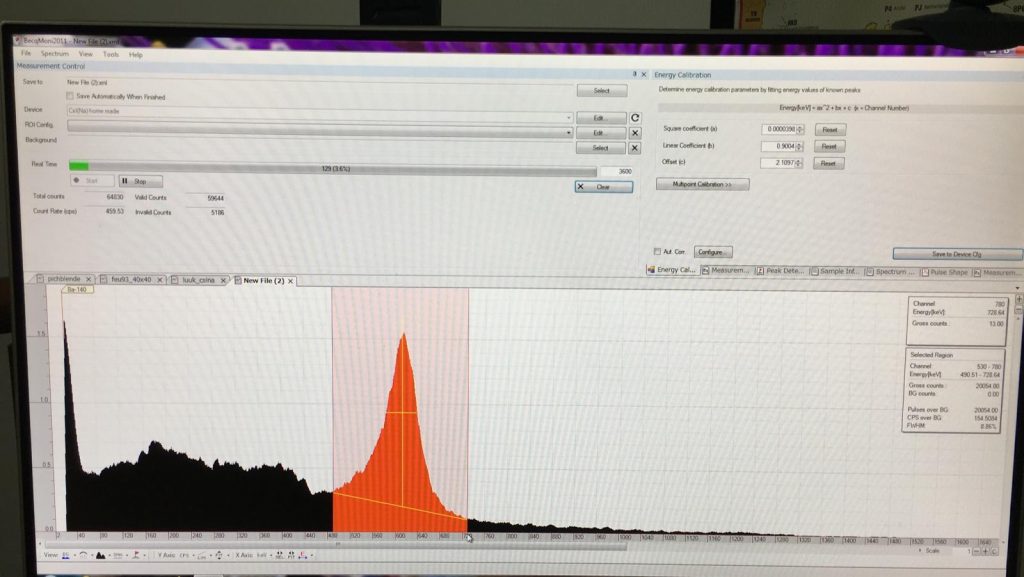

Even with just this rough grinding, when coupled to a FEU85 PMT, the crystal already provided a promising 8% FWHM at the Cs-137 peak.

Note: the FEU85 PMT itself typically has about 7% FWHM resolution at this peak.

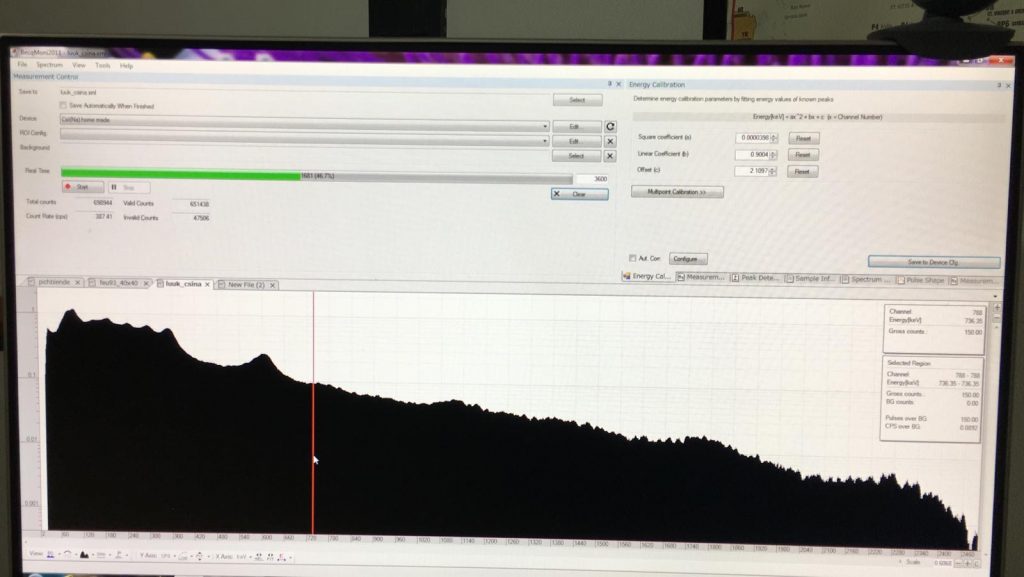

I finally decided to test the performance by taking a spectrum of my pitchblende sample. The result was very satisfying.

My next step will be to polish the crystal further and compare spectra to see how much the level of surface polishing affects its resolution (FWHM).