INTRODUCTION

During last weeks I’ve experimented with SiPM because I needed to investigate:

- Optimal positioning of SiPM along rectangular shaped crystals

- Optimal readout circuit

- Bias power supply

- Optimal reflective layer and preparation of crystal reflective layer

CRYSTALS

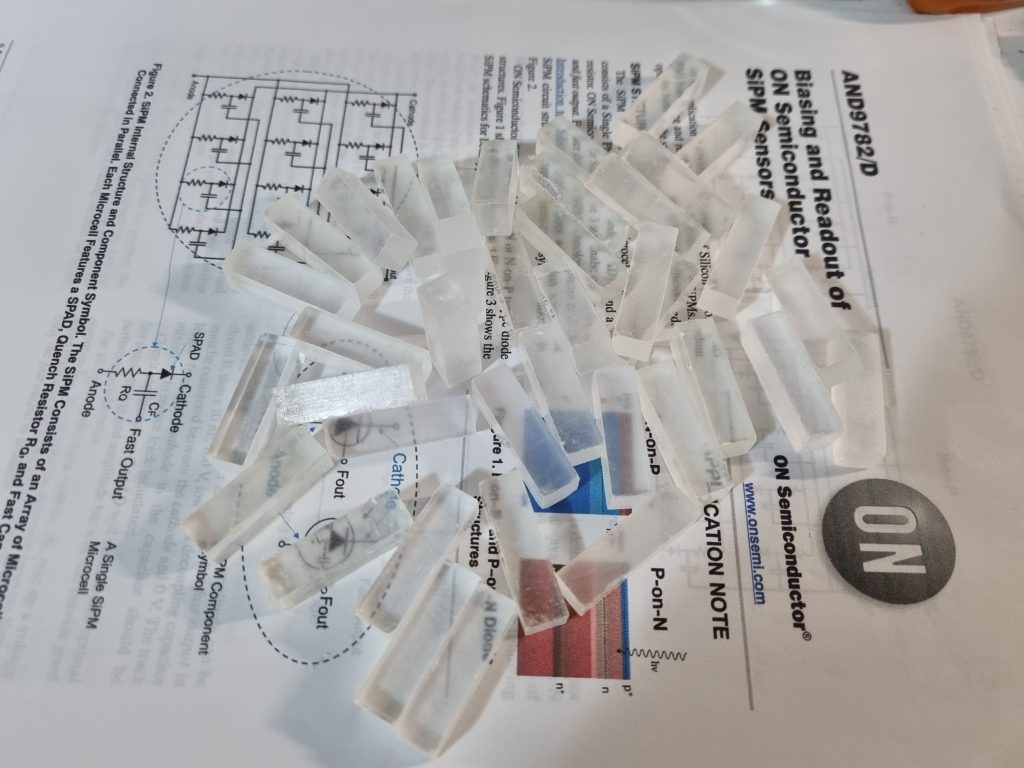

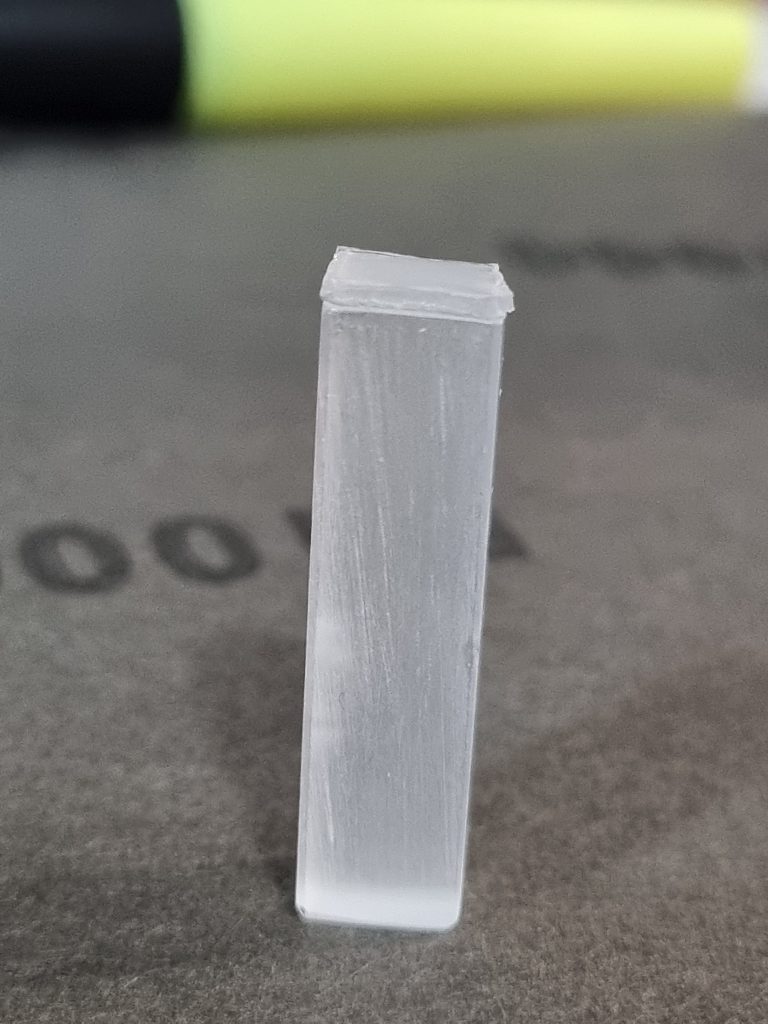

The crystals used where CdWO4 5x7x30mm and CsI(Tl) 8x8x30mm. Them are what I’ve found in quantity for cheap. An added bonus is that none of them are hygroscopic.

SiPM

I’ve used:

- MicroFJ-30035 3x3mm for positioning test

- MicroFC-60035 6x6mm all other tests

REFLECTIVE LAYER AND PREPARATION

CdWO4 material that I have is already prepared for assembly and so let’s talk about CsI(Tl).

DISCLAIMER:

The process make dust. It should be done wearing gloves and breathing mask. CsI(Tl) have toxic tallium dopant so be careful to don’t pollute with dust yourself and the environment.

I’ve bought an 8x8x30mm stock of CsI(Tl) scintillators some time ago. It went with rough surfaces and with some imperfections, first test gived me 6.4% and 10%. What a wide range!!! Them need to be prepared, polished and assembled into a proper detector to get some consistency.

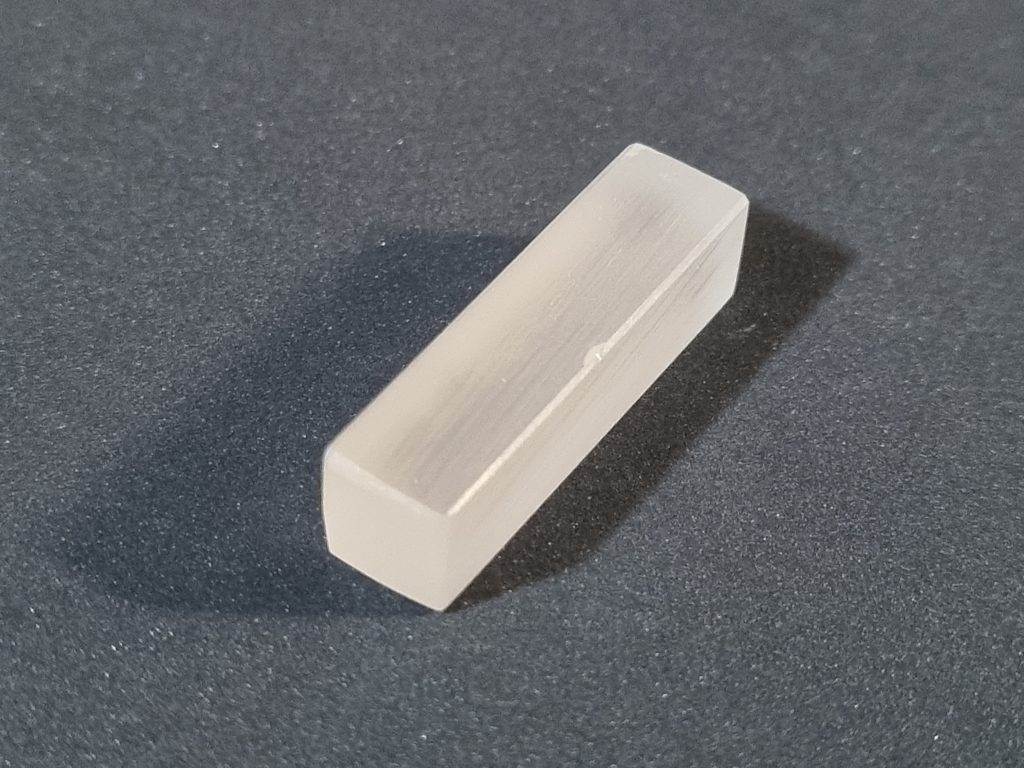

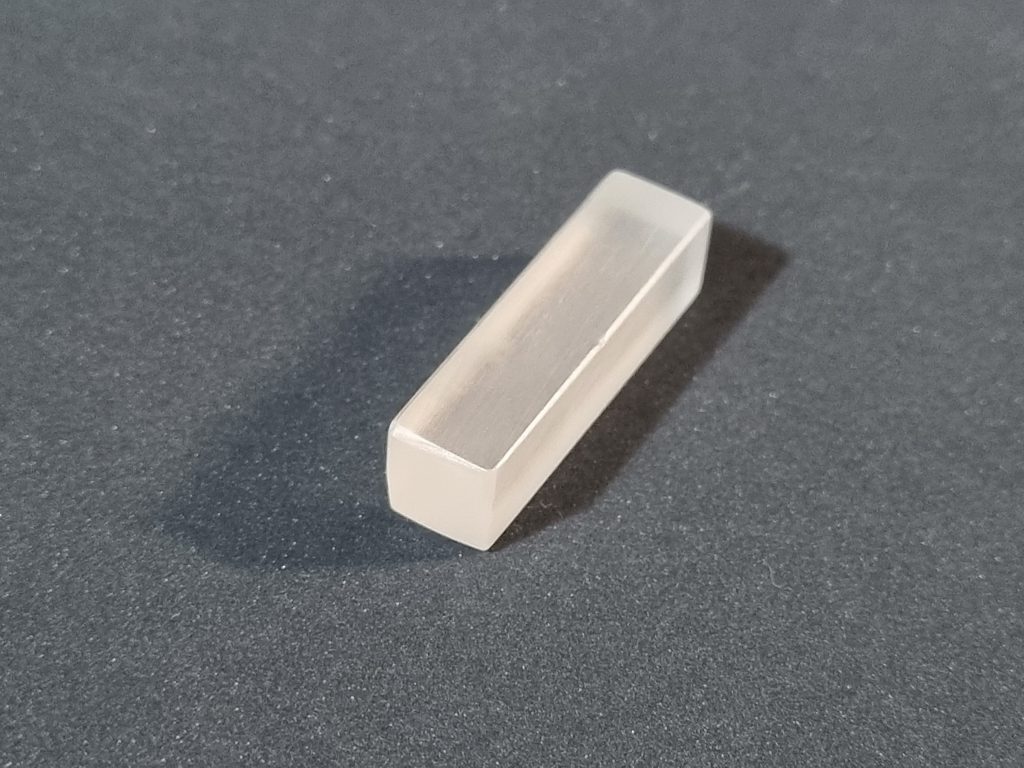

To prepare them for use I should first sand with some 800 grit sandpaper all the surfaces.

I’ve also smoothed a bit edges.

Next step it’s clean up with some alcohol applied over a soft tissue.

Now it looks much better, clear! It’s time to couple it with SiPM and add reflective layer.

SiPM POSITIONING AND OPTICAL COUPLING

I’ve tested various position where to attach the SiPM over the crystal. Any position tested gives different result so I’ve to determinate wich is the best one that gives the optimal performance. Resulted that it should stay at one end.

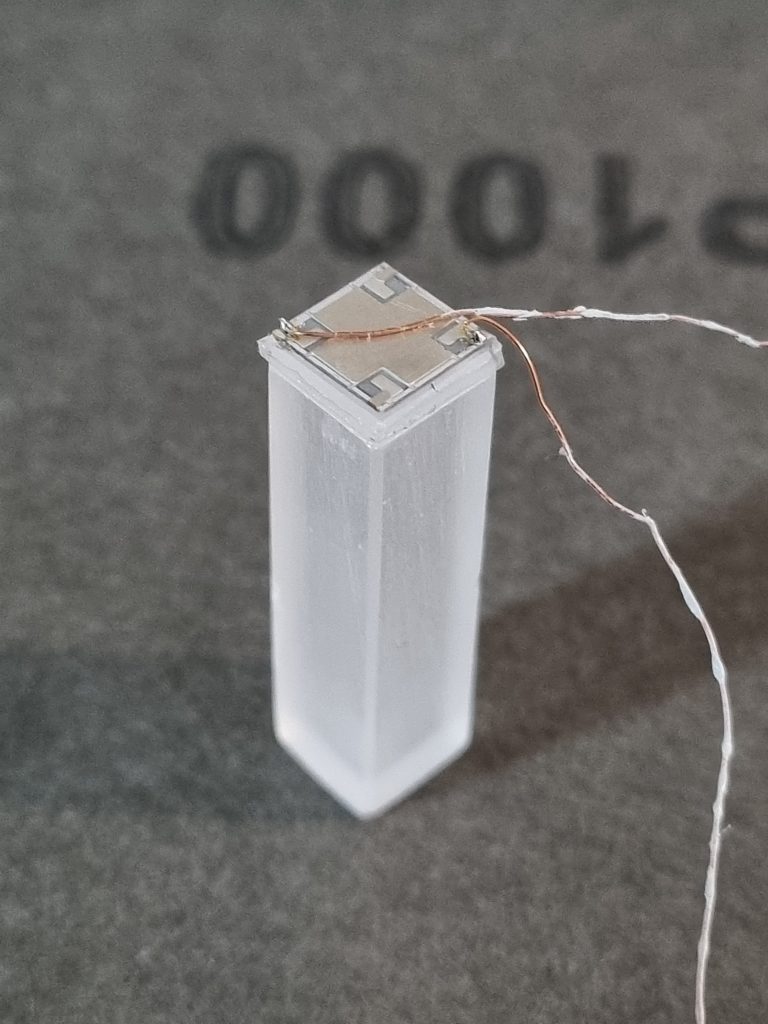

How to couple the SiPM with the crystal? It could be coupled with a drop of silicon optical grease, transparent grease or in my case some special optical flexible sticky double side tape.

First I’ve applied the special coupling optical sticky tape.

SiPM glued in place. I’ve soldered two small enameled copper wire directly to SiPM prior to this point.

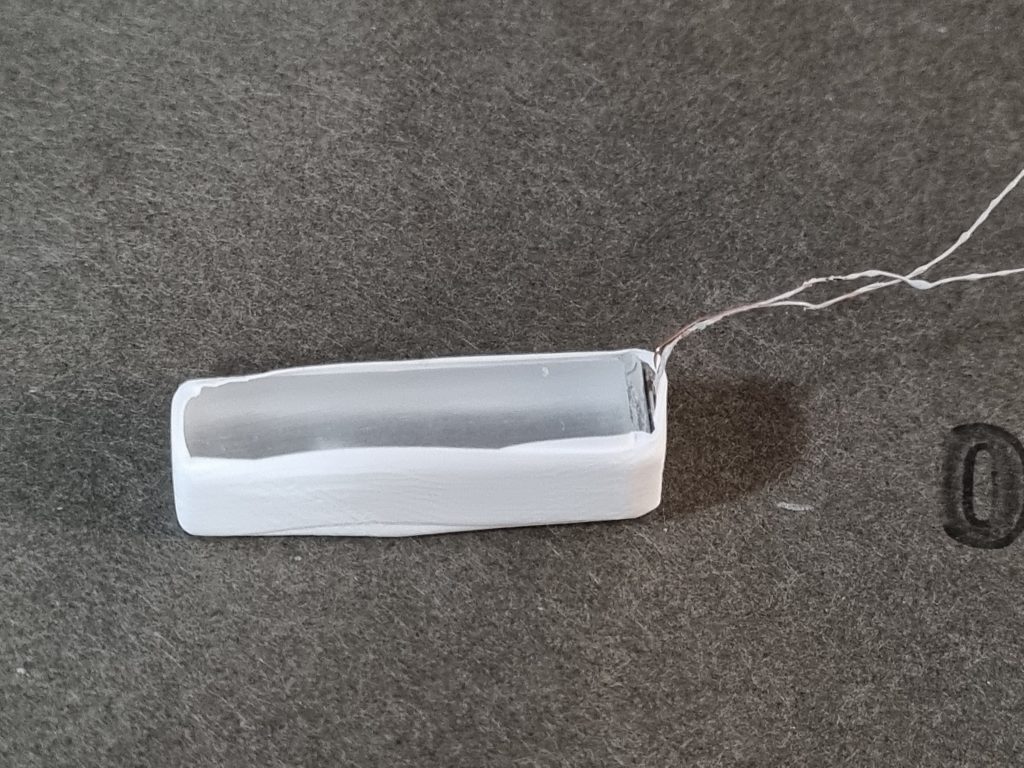

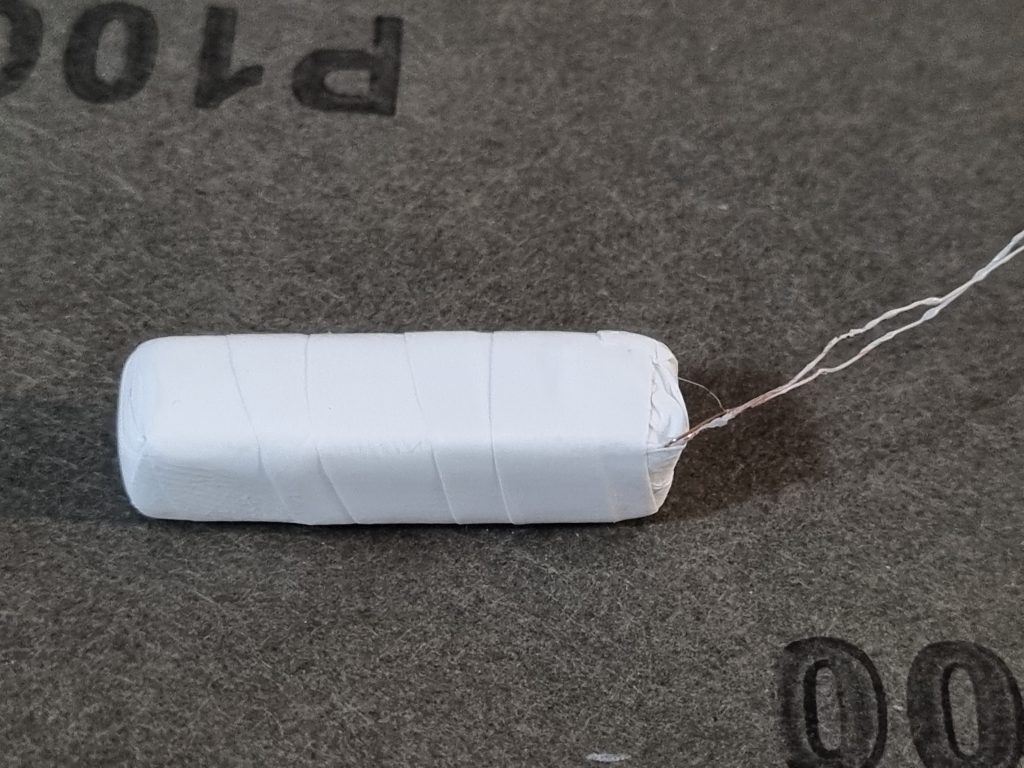

The crystal is wrapped in PTFE tape. I use standard unsintered PTFE tape 0.2mm thick for hydraulic use; 5 layers in total very tight wrapped. Experience with various reflective material like Titanium Wite paint and acrylic white paint shows that PTFE tape gives the best result.

Finally the detector is ready but not untill that I’ve putted around aluminium tape or black tape to prevent light ingress.

READOUT CIRCUIT

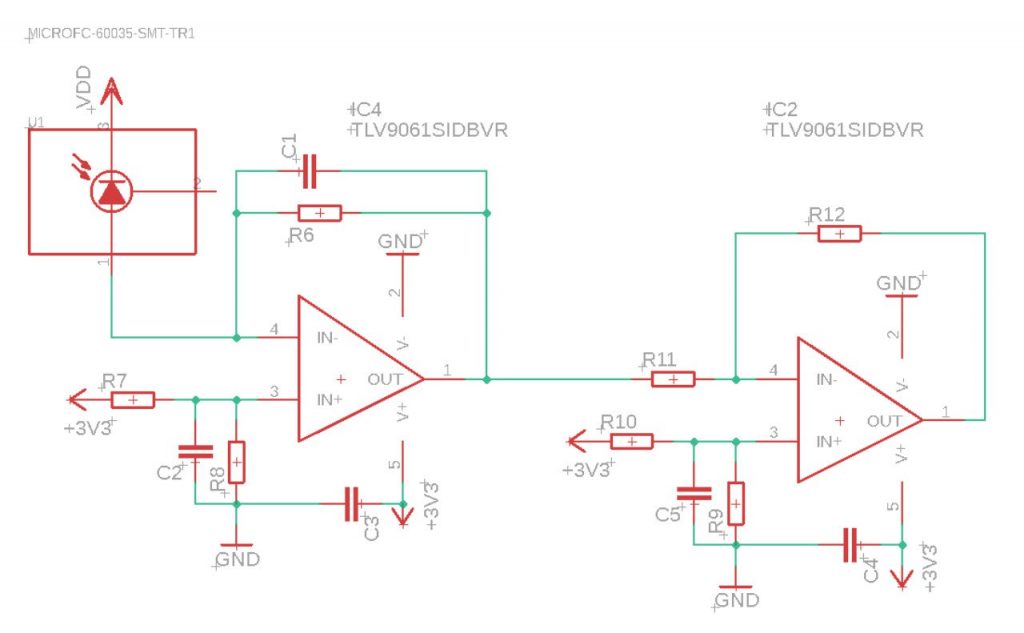

For pulse extraction from the SiPM I’ve found that trans impedance amplifier (TIA) is the best overall circuit. It gives better noise immunity and widest bandwidth.

IC4 it’s used to implement a TIA with gain set by R6. Optimal value could be between 470R and 10k. I use 3.3k. C1 is for compensation to prevent oscillation of the loop. It must be found experimentally but I use 470pF and found that works excellently.

IC4 bandwidth must be 10x the bandwidth of input signal. Indicativelly 10Mhz for CsI(Tl) and CdWO4 and 30Mhz to 50Mhz for NaI(Tl). Higher opamap bandwidth could be used too.

Please note that R6/C1 tau will affect pulse shape!

R7-8 and R9-10 sets an offset to the opamp. I use 10k for all of them so the signal at the output could be positive or negative by 1/2Vcc.

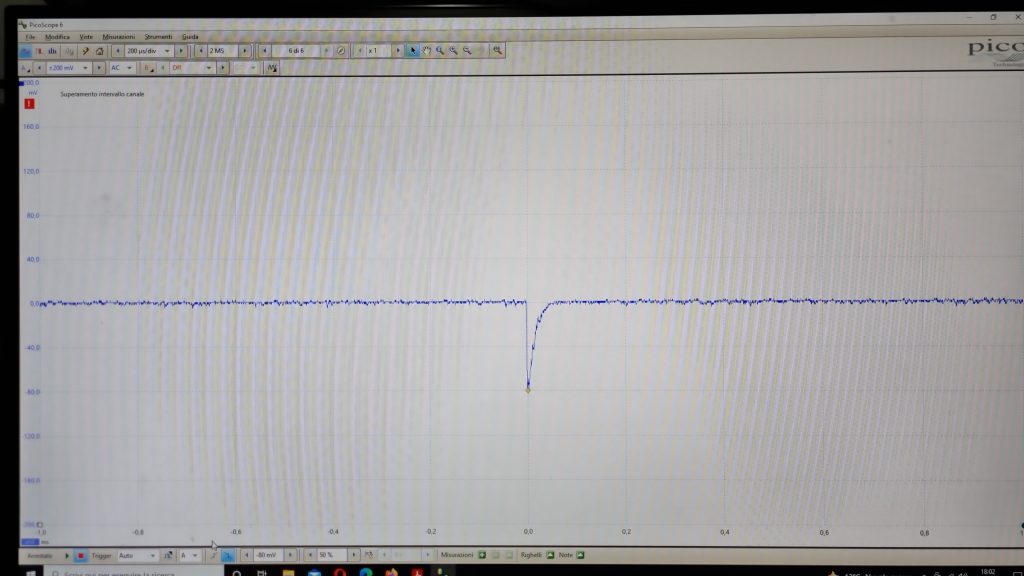

The output pulse shape is exactly as expected, fast rising front with exponential decay tail. The second opamp in inverting configuration is used as amplifier and buffer. It gives positive pulses to the next stage.

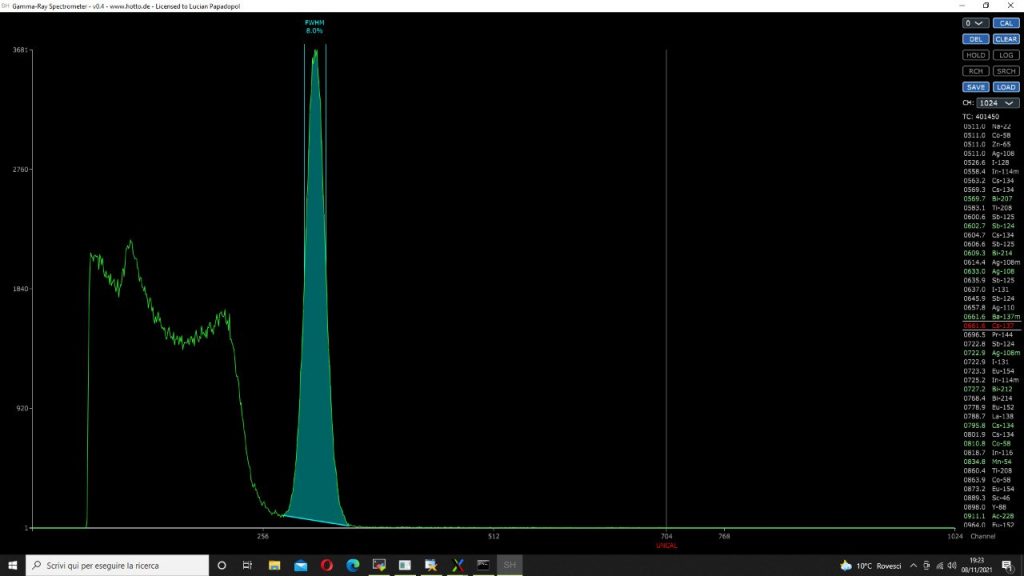

The signal at this point could be sent to a shaping amplifier and then feeded to an ADC + MCA to make gamma spectra. The crystal shown on this post gives 8% from original 10% not prepared.